Our Services

Delivering precision-driven infrared services that optimize your processes, protect your assets, and power your progress.

Paul C

Solution Partner

Thermography Services

You can Thermography servicesschedule a thermography study with our expert staff, and we can find the best infrared solution based on the requirements of your industrial automation applications. Our team comprises only ITC Certified Thermographers who will visit your facility and conduct infrared thermography inspection services.

Benefits of using infrared imaging:

- Rapidly troubleshoot heating processes and industrial equipment

- Fine-tuning a heating process

- Capture radiometric temperature data of your processes and equipment

Engineering Solutions

We have more than ten years of experience in the engineering field and can offer solutions to keep your systems up and running. Our team of professionals is composed of experienced engineers and thermographers who have tackled some of the most challenging projects in the industry.

Process Optimization

We can optimize your different processes through process optimization, making your system more manageable and more effective. Creating a foolproof strategy without violating any constraints in your industrial heating allows us to simultaneously improve your efficiency and throughput and minimize costs.

Other benefits of process optimization:

- Improved efficiency

- Better adaptability

- Reduce risks

- Streamlining operations

The goal is for your process to function better than before, and we can help you achieve that. We offer process optimization services to make sure your heat-related processes run smoothly.

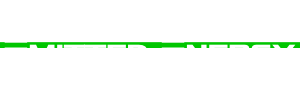

IR Weldability Study

Benefits of Infrared Weldability Studies:

- Determine the weldability of materials using IR

- Gather Radiometric Data of your material during heating cycle

- Understand the optimal heating recipe for IR welding process

We can conduct an infrared heat study to help you understand how thermal energy can benefit your company. Thermal cameras are used to view and monitor the heat and stability of an industrial component. It’s helpful in terms of maximizing efficiency in an automated assembly line.

Another service we offer is material studies, which is about helping you understand the materials of your process. We’ll help you understand why a material behaves the way they do and how it can affect your operation. We can also recommend materials depending on their compatibility and performance with other materials used in the system.

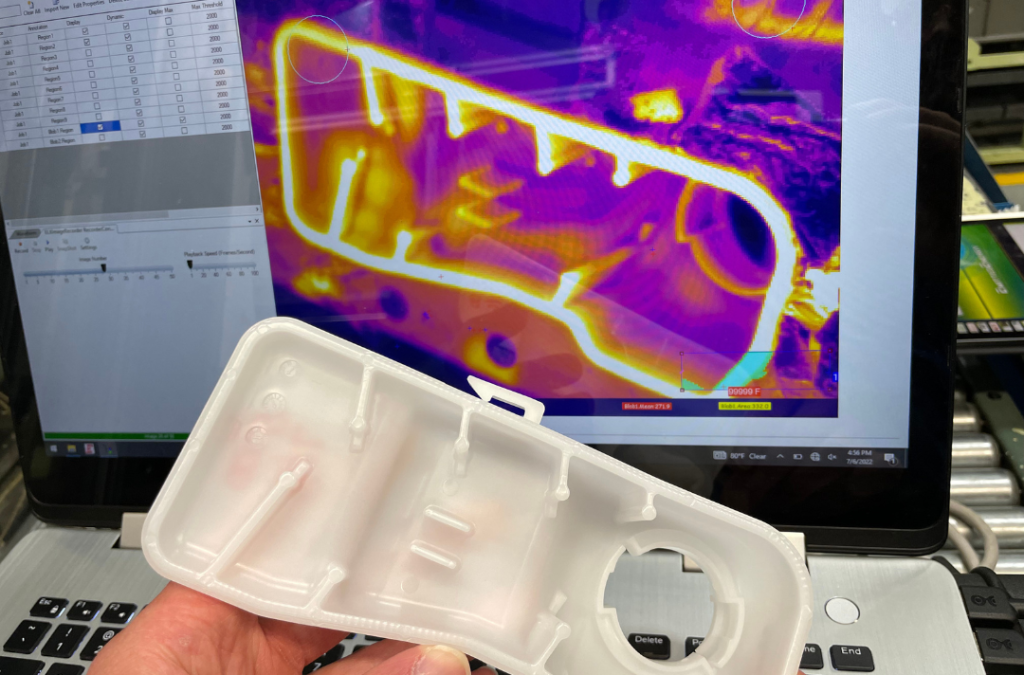

Thermal FEA

Finite Element Analysis allows for analyzing and simulating the behavior of structures and systems. And a critical factor in FEA is thermal analysis, which is learning about a system’s temperature and heat distribution.

FEA can accurately predict how the heat will flow throughout the process, which is important since the temperature changes over time. Plus, our engineers can develop the best design with the help of FEA to optimize thermal performance.

FLIR Camera Recertification

Certification and General Maintenance package for the FLIR thermal camera offers a complete multipoint inspection and validation service (for one lens combination). If eligible, Emitted Energy Energy will provide a replacement loaner camera during the certification period and will assist with connecting the cameras to your system.

Not sure what you need?

Talk to one of our experts

Choose Emitted Energy Corporation for Your Industrial Heating Needs

With our help, we can find the best solution for your industrial heating needs. Choose from our services above, and we can find a solution to ensure your systems and equipment run effectively without problems.

If you have any questions or concerns, don’t hesitate to contact us today. Our team of engineers will choose a solution that will work for you. We guarantee outstanding service and the best outcomes that will exceed your expectations.

Trusted by Businesses Worldwide

Let’s talk about your production challenges and how we can help overcome them with precision thermal solutions.