Packaging and Sealing

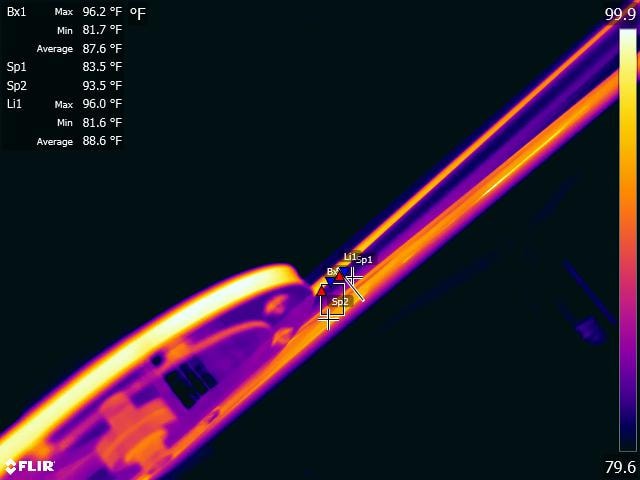

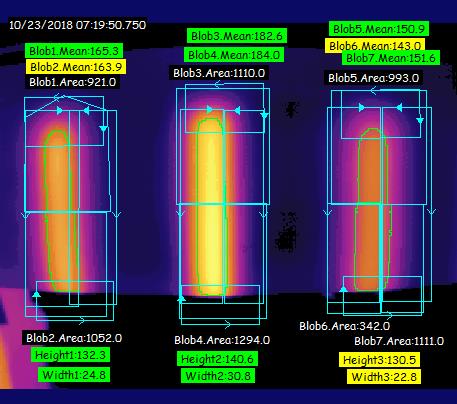

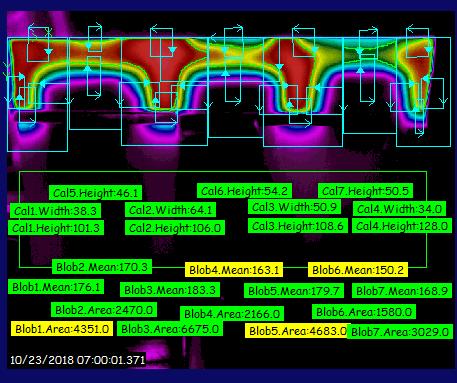

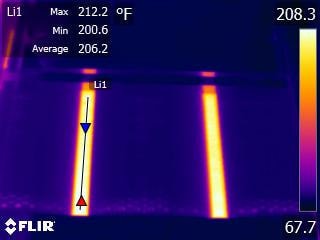

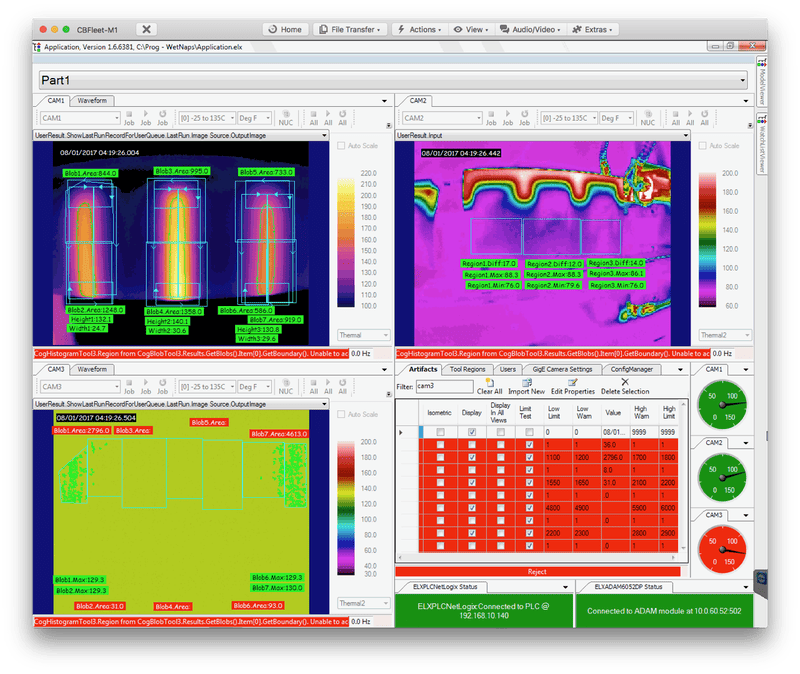

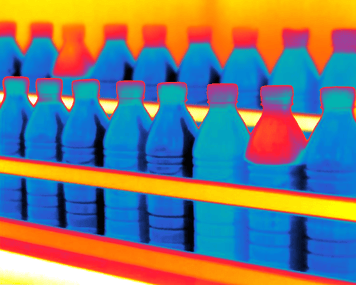

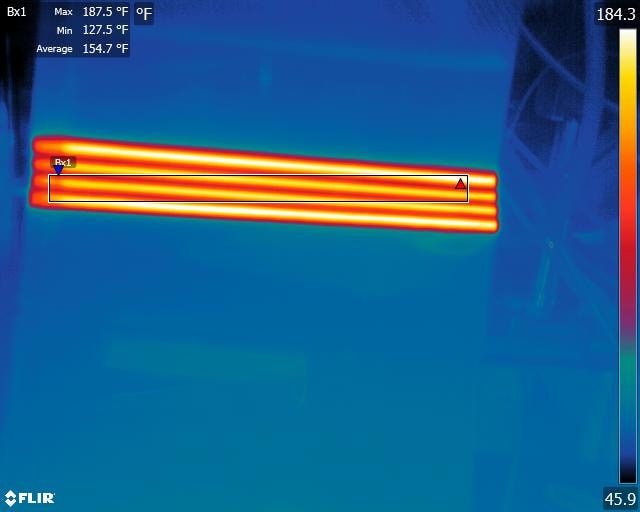

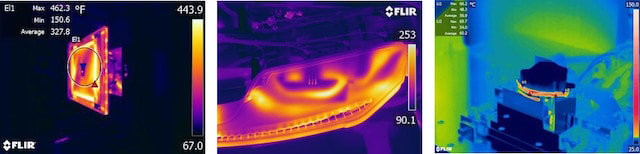

Are your processes being optimized with automated inspection for quality control and sustainability? Thermal imaging solutions can be a valuable tool in packaging and sealing processes. These solutions use specialized cameras to detect heat signatures and provide a visual representation of the temperature across the surface of an object. This information can be used to identify potential issues in the packaging and sealing process, such as inadequate heat sealing or uneven distribution of heat.

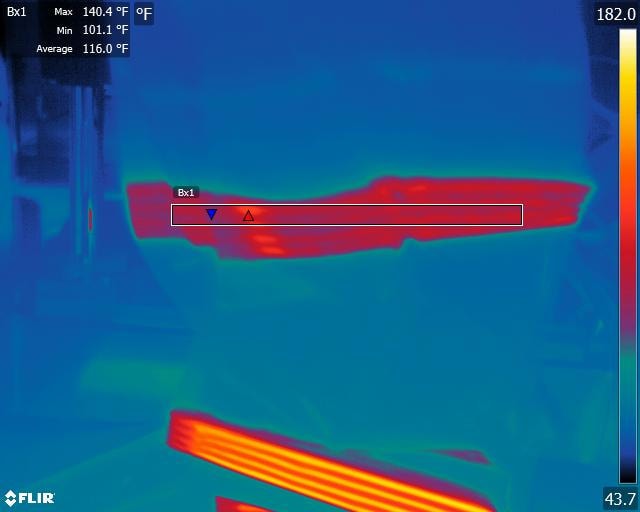

In packaging applications, thermal imaging can be used to ensure that packages are properly sealed and that the contents are adequately protected. By detecting heat signatures at the seals of a package, thermal imaging can help identify areas that may be prone to leaks or other potential issues. This can be particularly useful for sensitive items such as pharmaceuticals or perishable goods, which require careful handling and secure packaging.

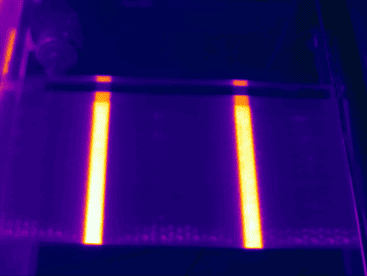

In sealing processes, thermal imaging can be used to monitor the distribution of heat across the seal. This can help identify areas where the seal may be weak or uneven, allowing operators to make adjustments and improve the quality of the seal. This can also help reduce waste by identifying potential issues before they become a problem, saving time and resources in the long run.

Overall, thermal imaging solutions can provide valuable insights in packaging and sealing processes, helping to improve the quality of the final product and reduce the risk of costly issues down the line. By detecting heat signatures and providing a visual representation of temperature, these solutions can help identify potential problems and ensure that packages are properly sealed and protected.